In-Mold Decorations: Integrating Style and Manufacturing Excellence

In-Mold Decorations: Integrating Style and Manufacturing Excellence

Blog Article

Discovering the Art of In-Mold Decorations: An Extensive Check Out Methods and Developments

When it comes to in-mold decors, a marriage of creativity and precision emerges to redefine the possibilities of layout. From the advancement of methods to the introduction of innovative products, the landscape of in-mold decors is a canvas where development flourishes.

Evolution of In-Mold Decor Strategies

The evolution of in-mold design methods has considerably progressed the visual possibilities and effectiveness of product design in making procedures. In the past, traditional approaches of embellishing items commonly involved post-processing actions that were taxing and included complexity to the manufacturing line. Nonetheless, with the intro of in-mold decor (IMD) strategies, suppliers can now flawlessly integrate attractive elements straight into the molding procedure.

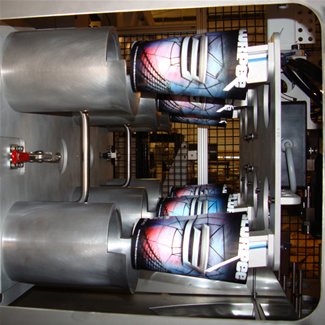

Among the crucial developments in IMD strategies is the ability to attain elaborate styles with remarkable information and clearness. By utilizing technologies such as high-resolution printing and progressed mold and mildew surface area therapies, manufacturers can develop aesthetically sensational decorations on items ranging from consumer electronic devices to automotive parts. In addition, IMD techniques have enabled the consolidation of structures, coatings, and colors that were formerly hard to attain with standard design approaches.

Advanced Products and Technologies

Progressing the center of advancement in production, the combination of advanced products and technologies has actually revolutionized the landscape of in-mold design strategies. Advanced products such as special polymers and nanocomposites offer boosted durability and visual homes, enabling vivid colors and complex designs to be integrated seamlessly right into the end product. These materials likewise give enhanced resistance to ecological aspects like UV radiation and chemicals, boosting the longevity of the decors.

Technological advancements, such as electronic printing and 3D surface texturing, have more broadened the opportunities in in-mold decorations. Digital printing allows high-resolution graphics to be directly related to the mold surface area, leading to precise details and sharp photos. On the other hand, 3D surface texturing techniques develop tactile effects that enhance both the sensory and visual charm of the embellished products.

The harmony between innovative materials and innovations not just elevates the looks of in-mold decors yet additionally boosts performance in the production procedure, making it more cost-efficient and eco-friendly (In-Mold Decorations). This assimilation paves the means for unlimited imaginative opportunities in the realm of in-mold design

Intricate Style Opportunities

Exploring the realm of in-mold decors unveils a globe of detailed style opportunities that site that press the borders of creativity and precision. Producers are no longer limited to simple patterns or layouts; rather, they can currently attain highly described and intricate decorations on their products. In-mold decoration methods enable the incorporation of fine lines, detailed textures, and vibrant shades that were previously challenging to attain with other techniques.

Among the vital advantages of in-mold decorations is the capacity to produce site link 3D effects, adding deepness and realism to the design. This technique opens a vast array of creative possibilities, making it possible for manufacturers to reproduce all-natural materials like timber grain or marble with unbelievable precision. Furthermore, in-mold designs can be made use of to create one-of-a-kind coatings such as glossy textures or metal effects, improving the total visual charm of the product.

In addition, in-mold decorations use exceptional precision, guaranteeing uniformity in style across a large manufacturing run. This degree of detail and precision is essential for industries where branding and layout integrity are vital, such as in the automotive or customer electronic devices markets. In general, the elaborate style opportunities managed by in-mold decorations remain to change the way products are embellished and developed in different industries.

Sector Applications and Developments

Structure upon the elaborate style opportunities facilitated by in-mold designs, various markets are using ingenious applications to boost item appearances and functionality. Furthermore, the customer electronic devices industry is leveraging in-mold decorations to produce sleek and modern-day devices with smooth styles that incorporate switches and displays right into the item surface area. By embracing in-mold decorations, these sectors are setting brand-new criteria for item layout and visual appeals, offering customers with aesthetically striking and innovative products.

Future Trends in In-Mold Decorations

Accepting progressing innovations and style methods, the realm of in-mold decors is positioned to witness substantial changes and innovations in the near future (In-Mold Decorations). Such innovations not just boost the visual allure of the products however likewise add functional worth, making in-mold designs a lot more than just a style element.

In addition, sustainability is ending up being a vital focus in the area of in-mold decors. Manufacturers are discovering eco-friendly products and processes to minimize environmental effect while keeping high-quality standards. This trend lines up with the growing consumer need for lasting products, pushing the industry towards more eco mindful methods.

Furthermore, personalization and customization are expected to play a significant duty in the future of in-mold designs. With developments in digital printing modern technologies and software application abilities, manufacturers will be able to use more customized options to meet individual consumer choices. This fad is likely to drive development and imagination in the design and manufacturing processes, giving individualized and unique items to consumers.

Conclusion

In-mold design techniques have actually read more advanced considerably, providing sophisticated materials and technologies that allow elaborate layout possibilities. These developments have actually located applications throughout different markets, bring about continual developments and future fads in in-mold designs. The art of in-mold decors proceeds to press limits and produce new possibilities for improving item looks and functionality.

Structure upon the complex style possibilities facilitated by in-mold designs, different sectors are taking advantage of innovative applications to raise product visual appeals and performance. Furthermore, the consumer electronic devices industry is leveraging in-mold decors to create sleek and contemporary gadgets with seamless designs that integrate buttons and shows right into the product surface area. By embracing in-mold decorations, these markets are setting new standards for product design and aesthetics, providing consumers with ingenious and visually striking items.

Report this page